Jigs are commonly used in drilling, boring, reaming, and tapping, while fixtures are used for milling, slotting, shaping, turning, and planning. Jigs are usually more expensive than fixtures. A plate jig improves the template jig by incorporating drill bushes on the template. The plate jig is employed to drill holes in large parts, maintaining accurate spacing with each other. The consistent quality of manufactured products is due to low variability in dimension. Cost reduction. Inter-changeability and high accuracy of parts. Inspection and quality control expenses are significantly reduced.

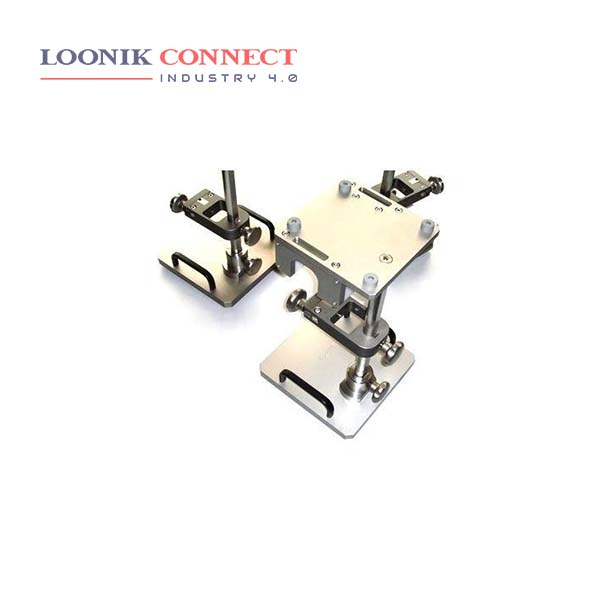

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Put simply, a jig is a manufacturing tool that guides and supports the component in order to produce finished products with the highest levels of accuracy which allows us to ensure that your plastic parts, pieces, and components are of the highest quality.

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools. Jigs are used in uni-dimensional machining processes like drilling, tapping, and reaming. Jigs are indispensable in the machining process. They help guide and hold workpieces to a specified location, thus ensuring that any drilling or tapping will be accurate.