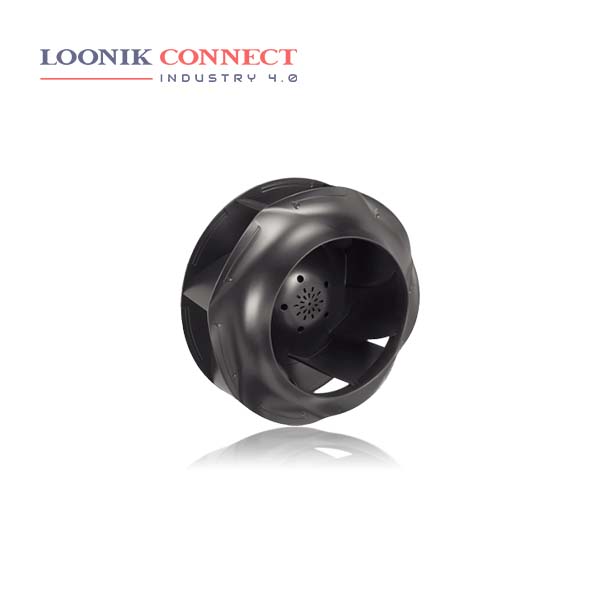

Centrifugal fans are based around a rotating wheel of blades called impellers, which drag the entering air or gas into a circular motion. It is then pushed out of the fan by the centrifugal force created by the rotation. The flow of air changes direction when both exiting and entering the fan. Centrifugal fans move air radially — the direction of the outward flowing air is changed, usually by 90°, from the direction of the incoming air. The airflow created by centrifugal fans is directed through a system of ducts or tubes. This helps create a higher pressure airflow than axial fans.

A centrifugal blower is a motor or pump that moves air using centrifugal force created by the rotation of an impeller that pulls air or fluids into the blower and pushes it out through the blower’s outlet. In the discussion of centrifugal blowers, the use of the terms blower and fan are used interchangeably. The centrifugal blowers are used in industries where there is a requirement for larger volumes of airflow with high pressure. They are highly useful in industrial processes like conveying material in dust collector systems, combustion air for burners, drying and cooling, general ventilation, and circulation of air.

What Is Centrifugal Force? Centrifugal force is a pseudo force in a circular motion which acts along the radius and is directed away from the centre of the circle. A centrifugal fan is typically used for residential applications to move air through a duct in your home. Think of your air conditioning system, furnace, or range hood duct. You also might see these in commercial environments like your car wash. Once the wash is complete, large fans dry your car off in just seconds.