A gripper is a device which enables the holding of an object to be manipulated. The easier way to describe a gripper is to think of the human hand. Just like a hand, a gripper enables holding, tightening, handling and releasing of an object. A gripper is just one component of an automated system. Grippers, sometimes called hand grippers, are primarily used for testing and increasing the strength of the hands; this specific form of grip strength has been called crushing grip, which has been defined as meaning the prime movers are the four fingers, rather than the thumb.

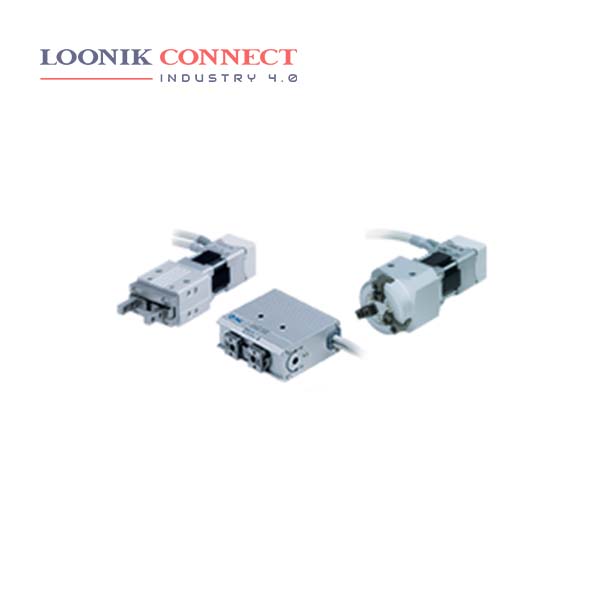

The four types of robotic grippers produce by collaborative robots companies are vacuum grippers, pneumatic grippers, hydraulic grippers, and servo-electric grippers. The vacuum gripper is the standard EOAT in manufacturing due to its high level of flexibility. Magnetic field sensors sense magnets internally mounted on gripper mechanism to indicate open or closed position. Proximity sensors sense tabs on moving gripper jaw mecha- nism to indicate fully open or closed position. Analog inductive proximity sensor continually tracks position of gripper jaws.

The gripper provides opening force, which should be enough for the coefficient of friction given by using metal fingers to suffice. The downside to the increase in force is a shorter stroke.