Jigs are commonly used in drilling, boring, reaming, and tapping, while fixtures are used for milling, slotting, shaping, turning, and planning. Jigs are usually more expensive than fixtures. A plate jig improves the template jig by incorporating drill bushes on the template. The plate jig is employed to drill holes in large parts, maintaining accurate spacing with each other. Advantages of Jigs and Fixtures Increase in production. The consistent quality of manufactured products is due to low variability in dimension. Cost reduction. Inter-changeability and high accuracy of parts.

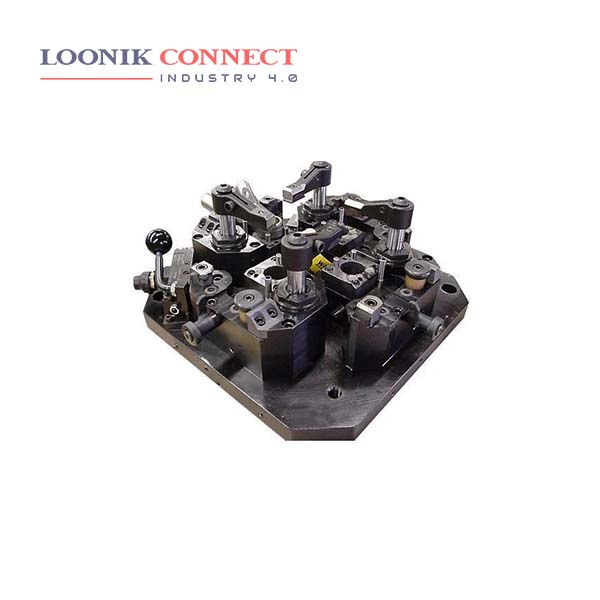

An indexing jig is used to drill holes that are spaced equally along a circle. In this example, four equally spaced holes are to be drilled on the periphery of the workpiece. The workpiece has a machined bore. The workpiece is located by a C-washer and a nut. A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability.

Jig control and guides the cutting tool to work at a predefined location on a workpiece. Fixtures are used for supporting and locating a workpiece. Fixtures do not guide the tool on a workpiece like a jig. Indexes are used to quickly locate data without having to search every row in a database table every time said table is accessed. Indexes can be created using one or more columns of a database table, providing the basis for both rapid random lookups and efficient access to ordered records.