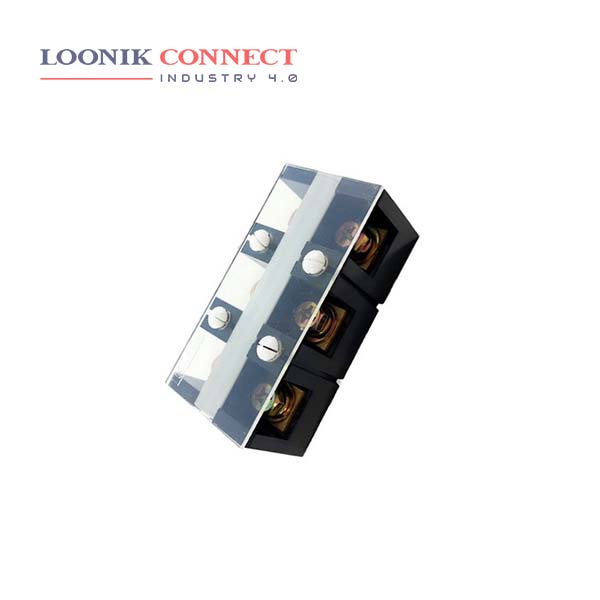

Terminal blocks are used to secure and/or terminate wires and, in their simplest form, consist of several individual terminals arranged in a long strip. Terminals are useful for connecting wiring to a ground or, in the case of electrical power, for connecting electrical switches and outlets to the mains. Terminal blocks are connectors that terminate a single wire and connect it to a circuit or other system. Terminal blocks come in a range of shapes, sizes and ratings, but always terminate a single wire (single pole) and are never multi-pole. The main purpose is that terminal/control boxes house and protect electrical connection points for multiple wires. They come in various sizes and are made of various materials such as glass-reinforced polyester (GRP). For durability, stainless steel screws are usually used for any fixtures within the boxes.

Terminal Block is a modular connector engineered for a reliable connection that secures two or more wires together, and manages complex electrical circuits. They are also used for connecting wires to ground or earth connections. Outer bodies of Terminal Blocks are ideally made up of melamine or polyamide material. Terminals come into three major categories: General cargo. Unitized cargo that can be carried in batches and handled by three specialized terminal types; break-bulk terminals, neo-bulk terminals (e.g. car terminals), and container terminals. Terminal blocks may be manufactured to fit one of several DIN rail sizes: Miniature top-hat rails are 15 mm wide. Terminal blocks that mount to this size can typically handle up to 300V. G32 rails are shaped like a letter ‘G’ and are 32 mm wide.

A terminal is the point at which a conductor from a component, device or network comes to an end. Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected. Steel is widely used to form enclosures because of its strength and malleability. Stainless steel is used rather than standard steel in environments requiring corrosion resistance and lightweight materials. Aluminum is a less expensive, lightweight, and more conductive metal that exhibits good resistance to oxidation.