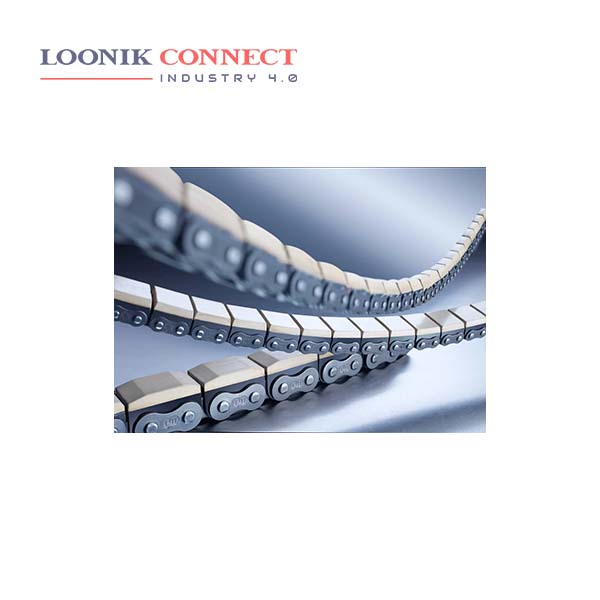

Roller chains with elastomer profiles are ideal for applications where fragile goods such as coated or thin sheet metal, planed timber planks or pipes require gentle conveyor handling. The chain has a rubber profile that prevents scratches during conveyor transport. The vulcanised elastomer profiles are available in various standard forms, and special profiles are available on request for specific applications.

Further advantages of chains comparing to belts: No sliding between the chain and the gear teeth. Negligible settlement which permits the chain to convey heavy loads. Long working life is expected owing to contact between deflection and friction between the support -surfaces, treated and separated by a layer of grease. In fact, the first metal chain was used as early as 225 BC. When chain was first created, it was primarily used as a way of collecting water. The very first chains were made in England by blacksmiths. The process developed in this time was used well into the 19th century until it became obsolete.

The links were connected to each other by three rings. There were brass handles at each end. People folded the chain up, link by link, and carried it in their hand. The name chain comes from these devices. By the late 1800s, the height of the Industrial Revolution had arrived, with the economical production of steel combined with the development in processing techniques. These advances helped the introduction of the first roller chain in 1880. The roller chain also features inner links held together by a pair of bushes